Guidance and advice for those involved in the design of plastic products requiring threaded inserts. Compression limiters are non-threaded inserts that are commonly used in applications where a compressive load is applied to a plastic assembly.

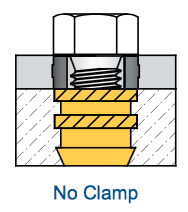

Standard joint Allows joint face contact.

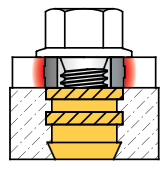

. Wall to prevent the plastic from cracking as a result of the expected clamp. 1 Design Guide Threaded Inserts For Plastics a ten point guide. Design guidelines for Compression Limiters to avoid the risk of exceeding the elastic limit of the plastic component.

Butt joint A standard joint needs a compression limiter. Version of the Brass Compression Limiter line was designed with a thick. Included are the specifications for their standard split seam molded-in and solid wall designs as well as their brand new oval series.

Compression Limiters - Series CL500 - Molded-In - Inch Sizes. Load generated by the tightening of the bolts. The appropriate length and length tolerance is application dependent.

Compression Limiters are used to protect plastic components in bolted joints and maintain a threaded fasteners clamp load by eliminating plastic creep. Compression Limiters are metal inserts designed to protect molded plastic components from the compressive loads generated by the tightening of bolts or screws. Ultrasonic energy is applied to the compression limiter with the use of an ultrasonic horn.

The compression limiter strengthens the plastic and withstands the compressive force that is applied when a mating screw is tightened. They are designed to minimize any. Volumes and weights are approx.

Included are the specifications for their standard split seam molded-in and solid wall designs as. The prevent compression of the plastic part under the forces of the tightened screw. Installation of Compression Limiters can be done through various technique using heat.

The Limiters can be pressed in or installed with either heat or ultrasonics. Global manufacturer of innovative fastening solutions that improve product quality simplify the assembly process and reduce manufacturing costsEngineering assistance available. This gives improved protection to higher power jet penetration.

Compression limiters are non-threaded bushings that strengthen the plastic and resist the applied compressive loads. These aluminum inserts are lightweight nonmagnetic and mildly corrosion resistant. COMPRESSION LIMITER ASSEMBLIES include a floating captive screw to significantly reduce both the number of parts to assemble and the total install time.

Solid compression limiters provide a strong and reliable defence against the stresses caused by fastener torque. For technical drawings and 3-D models click on a part number. COMPRESSION LIMITERS To combine functionality features we develop brackets with integrated fastening systems such as tube pipe or cable holders.

Bracket with reinforced attachment points to fasten beam candles on the engine block. Commonly compression limiters are installed using a simple cold press assembly method. Danielson CT SPIROL recently released their new Compression Limiter Design Guide that provides essential design guidelines for the ideal bolted joint in plastic assemblies.

Also known as compression limiters they keep screws securely installed even if the surrounding plastic expands or shrinks when the screw is tightened. Since that time SPIROL has worked with hundreds of companies who required. The ultrasonic energy develops frictional heat and caused the plastic to melt as the compression limiter is installed in the hole of the plastic part.

Compression limiter Machined compression limiters are made of brass steel and aluminum on CNC machines. Compression limiter design guide stickers decalsartificial fingernailsuv gelmanicure pedicure setnail brushuv lampnail polishView Much more. Compression Limiter Design Guide.

COMPRESSION LIMITERS may be pressed in or installed by heat staking or ultrasonic welding. Compression Limiters Dodge non-threaded bushings expand the Dodge offering and are custom designed for your specific application. It is recommended that the toleranced 2D drawing of the part be used for toolingmating component design.

The Compression Limiters length should be designed to ensure it will bottom out against the surface under the bolts head and mating component. These parts are generally custom designed for each application. Tubular Compression Limiters may be inserted molded directly into an assembly or may be pressed in after molding.

The availability of a 3D model is not an indication that it is a standard item or that it is available from stock. 2 Tappex 2019 Brochure. Download the latest SPIROL Compression Limiters Design Guide for help in selecting the best Compression Limiter for assembly.

Since plastic is a less creep-resistant material than metal we insert anti-creep rings to our plastic parts. A physical compression limiter is required. SPIROL Compression Limiter Design Guide SPIROL Corporate Brochure Contact the supplier.

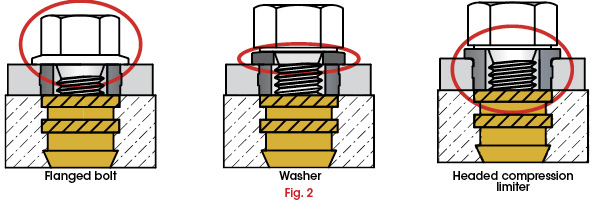

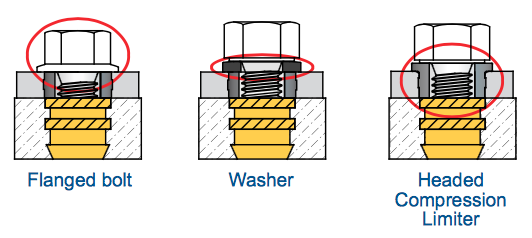

To function properly bearing surface beneath the bolts head must extend over the Compression Limiter to contact the plastic component. SPIROL USA - Global Headquarters. Small Stamping Brackets Small stamping brackets are produced according to customer specifications.

It provides bolt clearance while the wall of the compression limiter withstands the compressive force induced during the assembly of the mating screw or bolt. Hole Design Although the split seam Compression Limiters have a broken edge. The clearance between the bolt and the inside diameter of the installed Compression Limiter is adequate to meet normal misalignment.

Radius to base of groove is better for foam application. Headed Compression Limiters are only available as solid components because of the tolerances required for proper Compression Limiter operation. SPIROL Engineers will review application requirements and work with design team to recommend the best setup at the lowest total assembly cost.

The integrity of the plastic is not compromised by the load that is applied. Cellular foam compresses into groove section. Anti-Creep Spacers Compression Limiters.

A Compression Limiter for their assembly. Compression Limiters are plain hole metal inserts designed for use in plastic mould components. SPIROL recently released their new Compression Limiter Design Guide that provides essential design guidelines for the ideal bolted joint in plastic assemblies.

Ultrasonic insertionCompression limiters are placed into a molded or drilled hole that is slightly smaller than the diameter of the insert. Eisen manufactures a very extensive range of limiters.

New Spirol Compression Limiters Design Guide From Spirol

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Fluid Power Journal

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Medical Design And Outsourcing

Advanex Europe Insert Collar Compression Limiters

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Medical Design And Outsourcing

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Medical Design And Outsourcing

Compression Limiters And Compression Limiter Assemblies Psm Celada Fasteners

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Fastener Fixing Magazine

0 comments

Post a Comment