We have integrated on-line propaganda with off-line propaganda to build brand name recognization. Mechanical seals classified by Design.

An Introduction To The Five Key Features Of Good Mechanical Seal Design Reliability Matters

Labyrinth Seal Calculations.

. In systems with highly corrosive fluids are recommended mechanical seals with external springs. Other system factors that affect seal leakage rates besides. A precision machineis an integrated system that relies on the attributes of one component to augment the weaknesses of another component.

If so there is leakage of only vapor through the seal faces. Craig 3 Introduction Precision machines are essential elements of an industrial society. For an incompressible fluid k 1 where h1h2 the ratio of inlet to outlet face separation.

Im looking for a paper or design calculations for labyrinth seals used in liquid service. Where βhcc or hc1 γbaband Lis the effective length of the screwed portion. Mechanical Design Fundamentals K.

Bk19702 Mechanical 2 Oct 07 1534. Mechanical seal which seals the process fluid in a dual unpressurized seal. Mechanical seals are simply another means of controlling leakage of.

R 1 2698 mm 1062 in r 2 3175 mm 125 in h 0254 μm total surface roughness 10 μin ΔP 18 MPa 265 psi η 10 x 10 3 Pas 145 x 10 7 lbf-secin 2 See Equation 1 for how the theoretical leakage rate of a liquid. LIP SEAL Velan Recommended Values. The main calculation steps of the empirical design method for mechanical seal s.

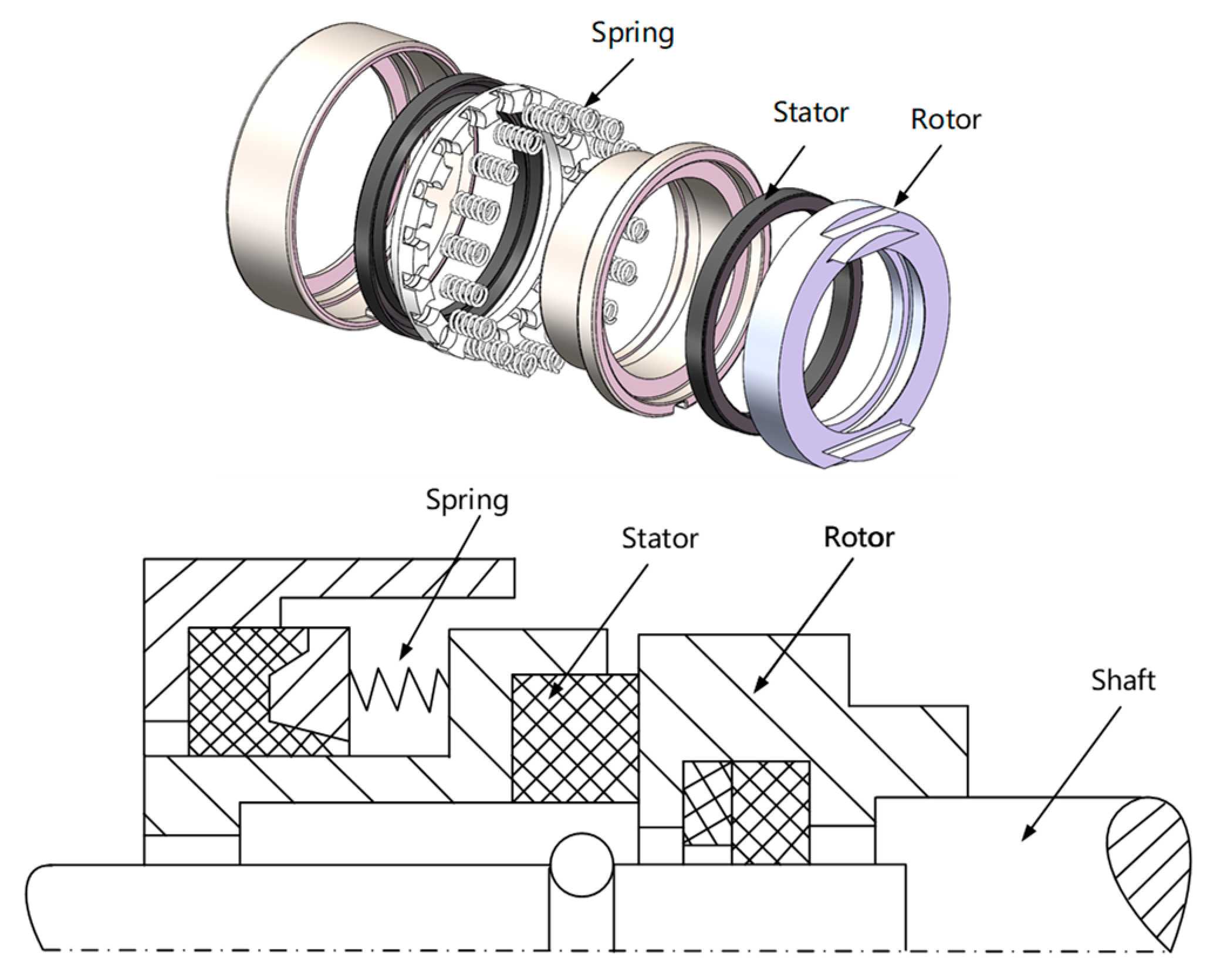

Mechanical-seal design in which the mating faces are designed intentionally to create aerodynamic or hydrodynamic separating forces in order to sustain a specific gap between the seal ring and the mating ring. Side-entering mixers are what the name. Iainuts Mechanical OP 8 Jan 07 1154.

PDF On Jan 1 2003 YGaft and others published Calculation and design of combined mechanical seal with self-adjusting clearance Find read. 12 Design An essential mechanical seal contains three sealing points. Spring load seal surface A 01.

To install a seal the pump would have to be taken off-line and disassembled. The PV value can be important because it represents both wear and heat generation. With the seal face rotating in clockwise direction rotating in clockwise direction L anti clockwise Looking from the stationary seat toward the seal face Looking from the drive side with the shaft with the seal face rotating in anticlockwise direction rotating in anticlockwise direction S independent of direction of rotation.

It is hoped that the application and design of the mechanical seal is suited for the service. This is due to various reasons. Calculations The bolt load is calculated to meet the operating load Wm1 or the gasket seating load Wm2 whichever is greater.

Seal Welding Provision Provision for seal welding is available for all bolted bonnet forged valves sizes 21224 65600 mm. Calculation to mean that the tested Kalsi Seals can handle 35000 psi at 10 ftminute or can handle 35000 ftminute at 10 psi. Packing Although mechanical seals had been around for many decades by 1955 industry had converted only a small percentage of pumps from packing to mechanical seals.

Thanks in advance for the help. A short collection of mechanical seal performance calculations has always been included in the earlier and current editions of the. The softer mechanical seal face usually has a smaller mating surface and is commonly called the wear nose of the mechanical seal.

In Equation 2 the pressure gradient factor k is taken as ½. The PV value is widely used as a guideline for mechanical seal design and application. Conditions such as temperature or pressure outside its design envelope can damage the seal and result in greater leakage rates.

Calculations must be performed for determining where to. Courtesy of Lightnin Obviously large custom motors would never be applied to a portable mixer but explosion-proof motors would. Mechanical seal design calculations We commit ourselves to expand the influence of DMS Seals brand to enhance the enterprise reputation and overall competitiveness.

At high Reynolds numbers Re 6001000 turbulent flow conditions lead to a more effective sealing action. The stationary part of the seal is fitted to the pump housing with a static seal this may be sealed with an o-ring or gasket clamped between the stationary portion and the pump housing. The new draft of the Fourth Edition of API 682 and the planned update of ISO 21049 include a significantly expanded version of these calculations plus.

In addition to selecting an appropriate seal ing surface specific pressure it is also required that the working pv value of the sealing pair is less than the allowable pv value. As someone already stated it is preferrable to obtain calculated seal chamber pressure from the OEM otherwise you can try to calculate yourself but you must be wary of the pump design. Specifically Im looking for calculations that give me leakage rates given a particular geometry.

Even though higher velocities do have negative effects on pressure sealing capability. Mechanical seals classified by Arrangement. Here we emphasize the design of mechanical and structural.

Assume that mass leakage approaches zero. Mechanical seals are designed to overcome these drawbacks. In low pressure applications the seating load is larger.

1252 MECHANICAL DESIGN OF MIXING EQUIPMENT Figure 21-3 Top-entering mixer with mechanical seal. Even so it has only a very rough correlation with overall seal performance. This is a common but completely erroneous usage of PV.

A short collection of mechanical seal performance calculations has always been included in the earlier and current editions of the seal standard API 682 and the co-branded version of ISO 21049. For the Reynolds equation to be satisfied one or more of the following statements must be true. This concept is also shown in Figure 2 where k 0 for line contact at the seal outside diameter and k 1 for line contact at the inside diameter when the pressure to be sealed is.

A ro 0 b p 0 c h 0 d 0 e µ 4 For a to be true the seal geometry would cease to exist. Rule of thumb for barrier fluid pressurization is 30 PSI above max seal chamber pressure. Typical values for the design parameters of helical seals are.

Calculate The Leakage Rate Of A Mechanical Seal Pumps Systems

Mechanical Seal Failure Flow Rate Calculation Mechanical Seal Engineering Eng Tips

Bushing Pv Calculations Daemar Inc

Energies Free Full Text Multifield Coupling Model And Performance Analysis Of A Hydrostatic Mechanical Seal Html

Calculate The Leakage Rate Of A Mechanical Seal Pumps Systems

0 comments

Post a Comment